A quality table saw will make completing nearly any woodworking project easier. The table saw is the center and essence of your woodworking workshop, All of the other tools are used and organized around it. You surely want to have the best table saw according to your budget and your needs. What are the main features of a woodworking table saw?. Which are some of the criteria to choose it?

Showing 1–12 of 31 results

-

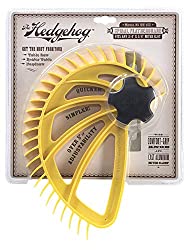

Premium Hedgehog Spiral Featherboard for Quicker, Easier, and Safer Workflow | Featherboard for Table Saws, Router Tables, and Band Saws

View Detail... -

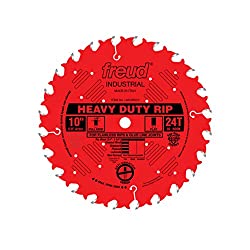

Freud 10″ x 24T Heavy-Duty Rip Blade (LM72R010)

View Detail... -

Powermatic 1791230K 64B Table Saw, 1.75 Hp 115/230V, 50-inch Fence With Riving Knife

View Detail... -

POWERTEC 71029 Magnetic Push Stick

View Detail... -

Big Horn 19105 Router Table Saw Push Block /Blade Depth & Angle Gauge, Hook Rule, Center Finder (Replacement of 19107)

View Detail... -

JET 708675PK XACTASAW Deluxe 3-Horsepower, 1Ph, 50-Inch Rip Fence

View Detail... -

Oshlun SDS-0630 6-Inch 30 Tooth Stack Dado Set with 5/8-Inch Arbor

View Detail... -

Milwaukee 2736-20 M18 Fuel ONE-Key 8-1/4 in. Table Saw, Tool Only – Battery, Charger NOT Included

View Detail... -

Safety Woodworking Push Stick 2 Pack, Each Has a Contoured Handle Embedded with Two Rare Earth Magnets, Ideal for Pushing Stock Through on Table Saws, Router Tables, Shapers and Jointers

View Detail... -

DEWALT Miter Saw Stand With Wheels (DWX726), Yellow

View Detail... -

Baileigh TS-1248P-52 Professional Cabinet Style Table Saw, Single Phase, 48″ x 30″ Table, 52″ Max Rip Cut, 5 hp, 220V, 12″

View Detail... -

The Cross-Cut Sled

View Detail...

Best time to buy a table saw for woodworking

There is no answer to this question without knowing your real needs. But if you already have most common power tools like Circular Saw, Power Drill, Jigsaw, Random Orbital Sander and you had used them satisfactorily, maybe it’s time to buy your first table saw. Also, think deeper on the tasks will be easier for you and the frequency you do them.

Woodworking Table saw buying guide (or How to choose a table saw)

As the Table Saw generally is central in the workshop, it is vital to buy the best table saw that suits your needs (and your budget), not the more expensive but the one with the features will make easier your work. For these see the “features” section in this same page and in the table saw specification you are going to buy.

What can you do with a table saw?

The table saw uses commonly are most of the task a woodworker do like cut, miter, square, shape, square, groove, and join pieces.

Based on this, you can check if it is important for you to fulfill the following conditions:

- The work surface should be heavy enough to resist the work it will take.

- See if there are connections for a dust collector

- Power (amps and horsepower): Should be enough depending on how hard is the wood you work and how deep are the cuts.

- Motor: should start with small to no fluctuation and run placidly

- The fence:

it should remain consistently parallel to the saw blade.

It should have fine tuning controls for when the fence needs adjustment if it becomes misaligned. - Safety: it has a blade guard

- Safety: on/off switch is easy to reach (See safety section for more)

About the blades, can be:

- Rip: to cut with the grain of the wood

- Crosscut: produces a very fine cut surface / can cut either with or against the grain

Combination

A quality table saw will make completing nearly any woodworking project easier.

These principles surely will help you to decide which table saw to buy.

Table Saw Features

There are many portable table saws that can be loaded in the bed of your truck.

Common features of Table saws could be (check on each product specification) :

- heavy work surface (the table), typically made of cast iron: will provide the saw with some heft for keeping the saw stable

- The saw that should have:

- a handle: raise and lower the saw blade easily

- another handle: adjust the angle of the blade

- A strong motor: that starts smoothly with little vibration and enough horsepower to make deep cuts through harder woods

- Rip Fence:

It should remain consistently parallel to the saw blade no matter where it is positioned along the length of the saw table - it should have fine tuning controls for when the fence needs adjustment if it becomes misaligned.

Miter Gauge: for making angled crosscuts. - Connection to a dust collector

Many quality table saws have:

- an arbor: long enough to be able to accommodate a full stacked dado blade set

- a removable throat plate: that can be replaced by zero-clearance inserts for protection when using a stacked dado blade set

Safety

Parts of the table saw designed for safety:

- a blade guard: to protect the woodworker from the exposed saw blade.

- a large, easily accessible on/off switch.

- large paddle switch: that is pulled to turn on the saw and pushed to turn it off: Generally should be easily pressed with your knee if you need an emergency off.

- anti-kickback pawls: to keep the wood from kicking back into the operator’s body

- riving knife: to keep the wood separated as it passes the blade and keeps it from pinching onto the blade

- Blade brake: stops the blade whenever a body part comes into contact with the blade.

Other optional features:

- tenoning jigs

- stacked dado cutting sets

- tapering jigs

- panel-cutting jigs

- sliding tables

woodworking table saw tips for beginners

First of all, read, re-read and read again and take seriously the manual especially the safety-related instructions.

Reading the manual gives you advice about how to use a table saw but puts at your fingertips many tips the experts do not give you for believing them obvious.

Again: Take seriously safety.

Beyond the table saw basics, as second important advice: take time to clean it. Be sure to turn off and disconnect it from power when cleaning. There are a number of commercial cleaners available to clean your saw blades.

Do not use any abrasives on your saw blades. Scrubbing cleansers and rough pads will leave scratches on the blade, which will only hold more pitch, making the problem worse the next time you need to clean the blade.

All saw blades dull over time, but your circular saw and table saw blades can be resharpened if they are carbide. Since carbide blades are more expensive, this feature makes the blade more cost-effective, since sharpening will prolong the life of the blade.

Your table saw will have a “table” for the stock you are working on. These tables are usually made of cast iron. Cast iron rusts easily. It will come with a special grease that protects the surface during storage. You’ll need to clean the grease off of the surface and apply a protectant in its place that won’t stain your stock or be a fire hazard. Just be very sure that you don’t use silicone wax because the residue interferes with the finish on certain woods.

And again. Take safety seriously

You may also like…

You need to measure twice to cut once. But you must have the most adequate woodworking measuring tools to do that.

Consider which are the woodworking tools you want to get to build the workshop of your dreams.

Review which helps do you have to the wood cutting activity including power, safety, and handtools.

What do you prefer to buy? Review portable and fixed alternatives for the Woodworking Bench, the place where most of your work will happen.